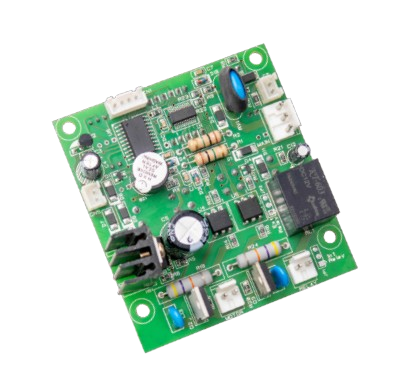

Voltage stabiliser

- Consumer Electronic Solutions

- Voltage stabiliser

Best PCBA ODM Solutions

“Bringing Your Brand Vision to Life with Precision.”Along with Brevera

Voltage stabiliser Innovations

Brevera Has Embedded testing mechanisms, such as in-circuit testing (ICT) and boundary-scan testing (BST), help ensure that PCBA assemblies meet strict performance standards. Testing early in the production cycle reduces the chances of defective stabilisers reaching the market.

Heat dissipation is critical for long-term reliability, especially in high-power stabilisers. Techniques like thermal vias, heatsinks, and thermally conductive PCBs help manage heat effectively, ensuring stable performance over time.

Innovations in power electronics have led to the use of high-efficiency components like MOSFETs, IGBTs, and efficient transformers in PCBA design. These components help reduce power loss, improve response time, and provide stable output.

Overview Services

Custom PCB Design: Creating layouts tailored to voltage stabiliser specifications, including component placement, power handling, and thermal management requirements.

Component Sourcing and Selection: Choosing high-quality components like transformers, resistors, and capacitors, optimized for stability and long-term durability in fluctuating voltage environments.

Prototyping and Testing: Rapid prototyping, functional testing, and iterative design adjustments to ensure robust performance and adherence to safety standards.

Automated Assembly: Utilizing SMT and through-hole techniques for precise and efficient component assembly, ensuring consistent quality and reduced production time.

Quality Control and Inspection: Implementing AOI, in-circuit testing (ICT), and functional testing to detect defects early and ensure each board meets stringent performance standards.

Conformal Coating and Encapsulation: Applying protective coatings to safeguard against environmental factors like humidity, dust and vibration extending the lifespan of the stabiliser.

Mass Production and Scalability: Scaling production efficiently while maintaining quality, enabling reliable supply for large-scale and custom projects.

Reliability

Minimum spark relay

switching technology

Self-adapting to

variations in relay

switching timing

EMI and thermal-tested

designs

Features

Robust solutions for

double-phase stabilisers

Complete range of

products from 60V-440V

and 500W to 10kW

Cost Efficiency

Lowest BOM cost

solution in the market

Custom made MCU

Custom built test fixtures

Head Office

- Brevera Technologies Private Limited 1st Floor ,Sai Arcade Bejai -Kapikad Road ,Bejai Mangalore-575004, Karnataka INDIA

- +91-0824 -2217028

- info@brevera.in

Manufacturing Unit

- Brevera Technologies Private Limited #70-Z2, Hootagalli Industrial Area Mysore – 570018, Karnataka INDIA

- +91 - 0824 - 2217028

- info@brevera.in

Brevera Template Kit by Ansible

Copyright © 2024. All rights reserved.